Basic Info.

Model NO.

Casting Parts

Surface Roughness

Ra0.8

Machining Tolerance

+/-0.10mm

Standard

AISI

Certification

RoHS, ISO 9001:2008

Shipment Time

3 Week to 5 Weeks

Deep Process

Precision Casting + Machining

Hardness

According to Requirement

Heat Treatment

T3-T8

Transport Package

Polybag and carton

Specification

Per customer′s drawing or sample.

Trademark

Per customer′s drawing or sample.

Origin

Ningbo, China

HS Code

7326901000

Production Capacity

2, 000pcs/day

Product Description

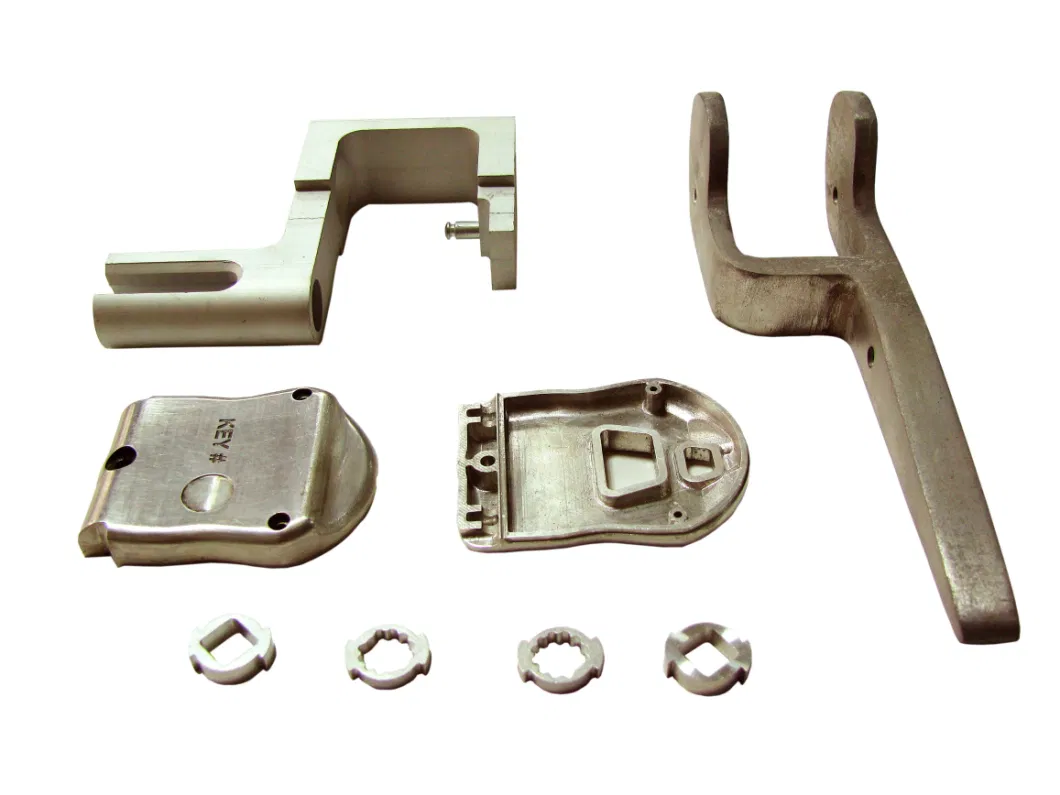

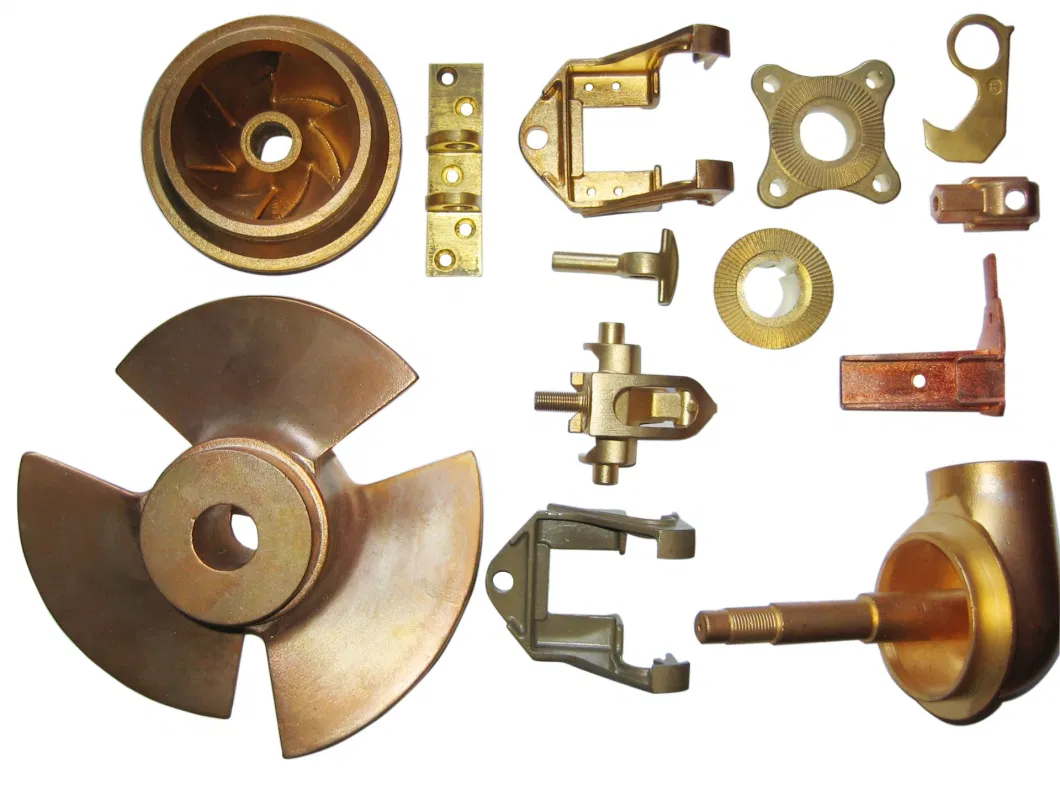

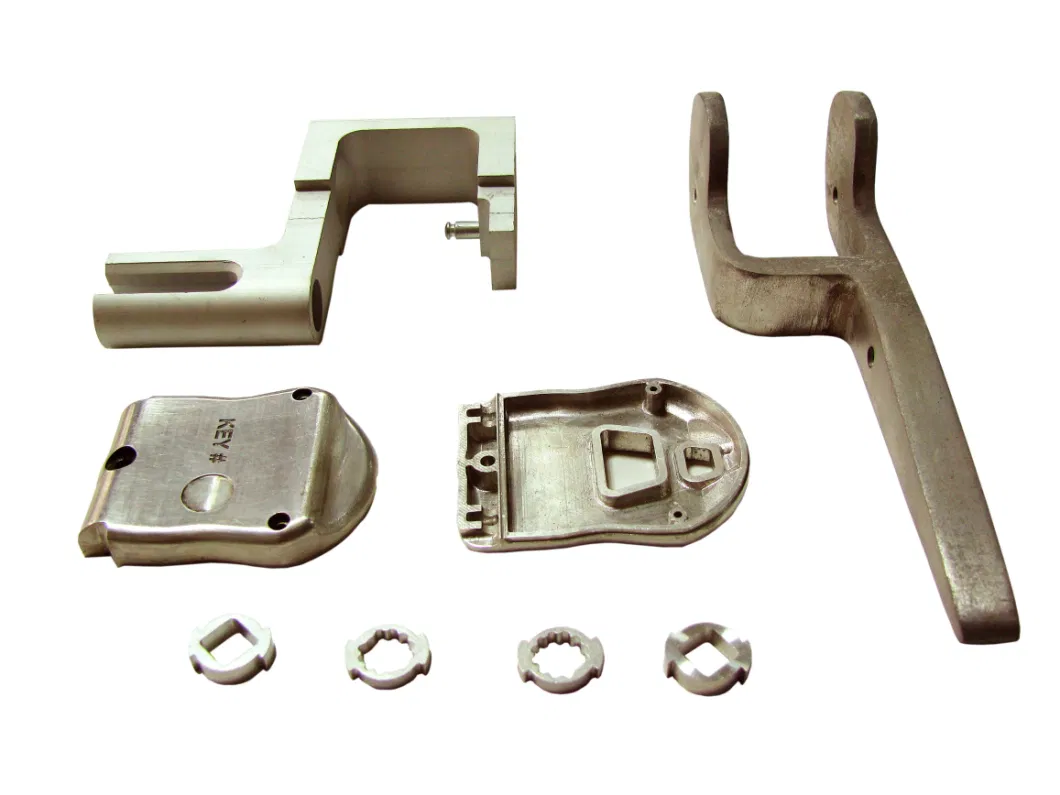

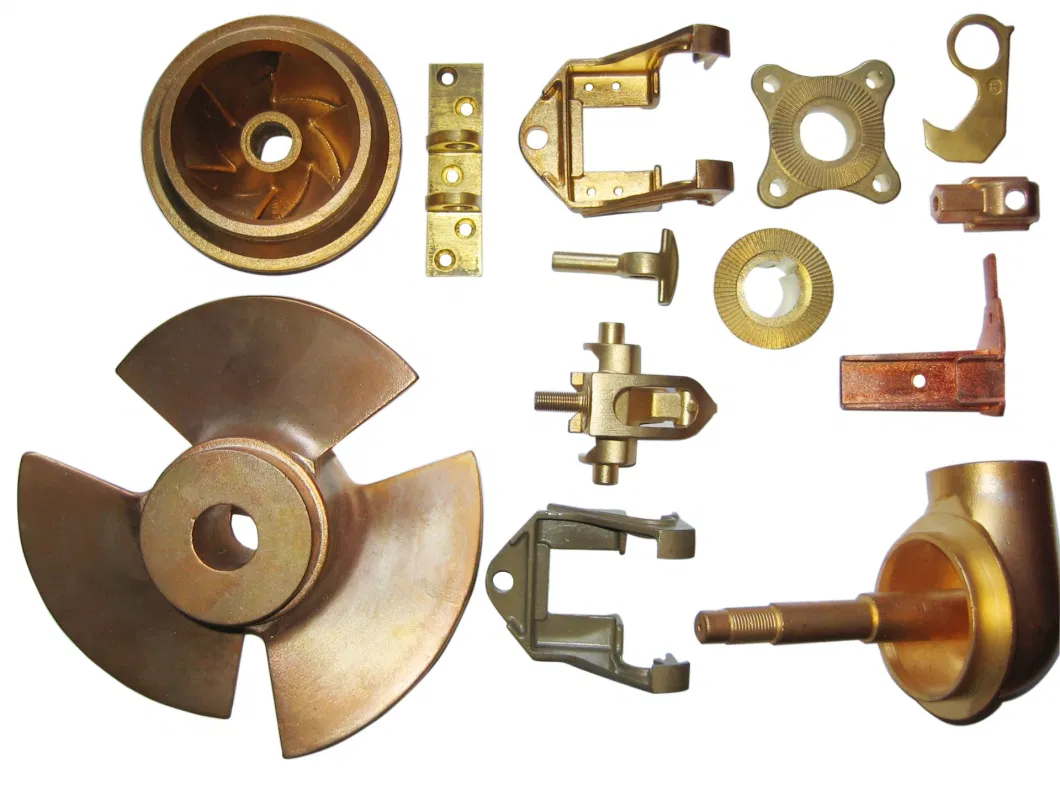

The description of products

* Software for drawings: Auto CAD, PRO-E, UG, Solid work, CATIA, etc.

* Surface treatments: Polishing, plating, machining, etc.

* Application: Auto Parts, Industrial parts, Machinery parts, Building Parts, Valves.

The introduction of our company

1.Customer-focused organization;

2.Smooth & quick communication;

3.Custom manufacturing & Engineering solution;

4.Excellent quality control;

5.Reasonable price;

6.Small order & on-time delivery;

7.Conduct the teamwork practice.

The package of our products

| Application | Heat dissipation |

| Material | ADC12,ADC10,A360,EN47100,EN44100, zinc alloy,Brass.Aluminum Alloy.etc. |

| Hardness | According to requirement |

| Surface Treatment | Clear anodizing, Black anodizing,powder coating,brushing; sand blasting; shot blasting;polishing |

| Deep process | Cutting, milling, drilling, punching, CNC ect |

| Packing | Carton, wooden pallet or by your request. |

| Shipment Time | 3 week to 5 weeks |

* Software for drawings: Auto CAD, PRO-E, UG, Solid work, CATIA, etc.

* Surface treatments: Polishing, plating, machining, etc.

* Application: Auto Parts, Industrial parts, Machinery parts, Building Parts, Valves.

Drawing→ Mold → Precision casting → Deburring → Drilling holes → Tapping → CNC Machining → CNC control center → Polishing → Surface Finishing → Assembly → Quality Inspection → Packing

The introduction of our company

1. Equipped with modern and precise manufacture equipments and strictly quality control which allow us to make high quality auto parts

2.High efficient management to achieve the production cost optimization, and return the profit to customer end for long term win win relationship.

Unimolding PRIMARY COMPETITIVE ADVANTAGES: 1.Customer-focused organization;

2.Smooth & quick communication;

3.Custom manufacturing & Engineering solution;

4.Excellent quality control;

5.Reasonable price;

6.Small order & on-time delivery;

7.Conduct the teamwork practice.

The package of our products