- Overview

- Product Description

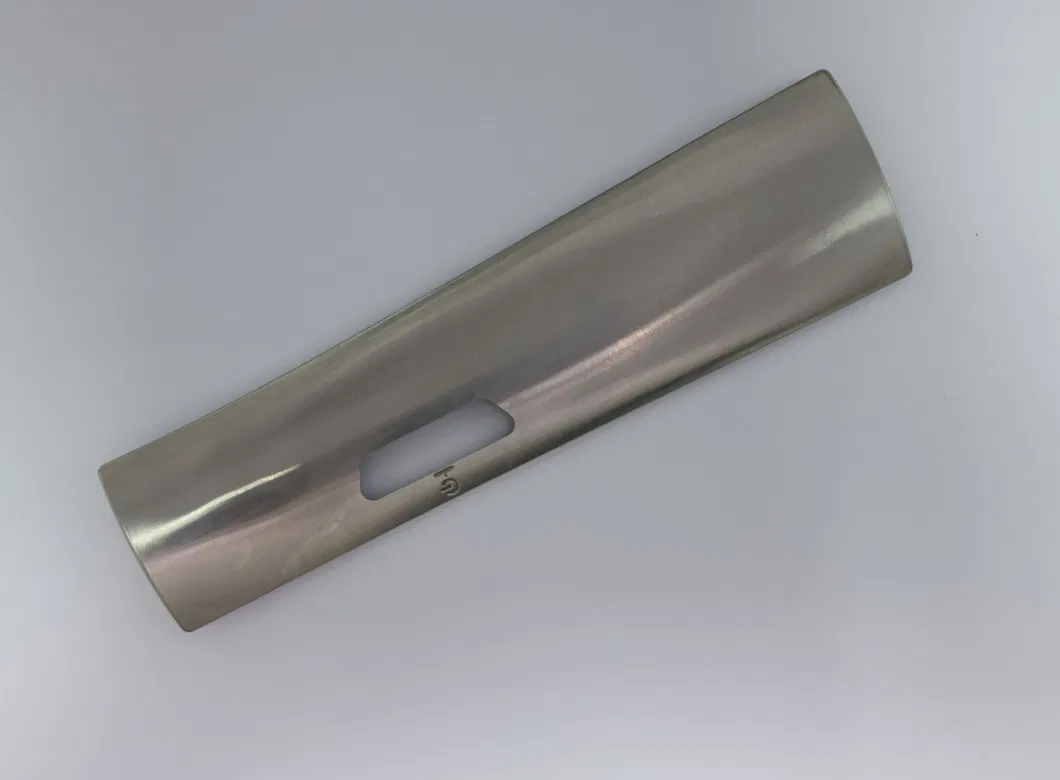

- Detailed Photos

- Product Parameters

- Certifications

- Company Profile

- FAQ

Basic Info.

Product Description

China Factory Custom Stainless Steel Precision Stamping with Punching Bending

Precision stamping is a remarkable technique that has revolutionized the manufacturing industry. With its ability to create intricate and precise metal components, it has become an indispensable process in various sectors. Today, we delve into the world of precision stamping, focusing on a specific aspect that sets it apart - stainless steel precision stamping with punching bending.

Stainless steel precision stamping with punching bending is a cutting-edge method that combines the durability of stainless steel with the precision of stamping and the versatility of punching bending. This technique allows for the creation of complex shapes and designs with utmost accuracy and efficiency. The end result is a product that not only meets the highest quality standards but also exhibits exceptional strength and resilience.

The key point of stainless steel precision stamping with punching bending lies in its ability to produce components that are not only aesthetically pleasing but also highly functional. The process involves the use of advanced machinery and tools, operated by skilled professionals who meticulously craft each piece to perfection. The combination of stainless steel's corrosion resistance and the precision of stamping and punching bending ensures that the final product is not only visually appealing but also capable of withstanding harsh conditions.

Industries such as automotive, aerospace, and electronics greatly benefit from stainless steel precision stamping with punching bending. The technique enables the production of intricate parts that are crucial for the smooth operation of these sectors. From intricate brackets and connectors to complex electrical components, stainless steel precision stamping with punching bending offers a solution that is both reliable and cost-effective.

In conclusion, stainless steel precision stamping with punching bending is a game-changer in the manufacturing world. Its ability to create precise, durable, and functional components has made it an indispensable process in various industries. Whether it's for automotive, aerospace, or electronics, this technique ensures that the end product meets the highest quality standards while offering exceptional strength and resilience. So, the next time you come across a finely crafted metal component, remember the intricate process behind it - stainless steel precision stamping with punching bending.

| Product | OEM Sheet Metal Parts |

| Material | Carbon Steel, Stainless Steel, Aluminum, Brass, Copper, etc. |

| Finish | Brushing, Polishing, Anodizing, Powder Coating, Painting, Plating, Silkscreen Printing, Sandblast, etc |

| Process | Laser Cutting, Precision Stamping, Deep Drawing, Bending, CNC Punching, Threading, Riveting, Drilling, Welding, etc |

| Drawing | jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc |

| Test | CMM,Digital Height Gauge, caliper, Coordinate measuring machine, projecter machine, roughness tester, hardness tester. etc |

| Certificate | CE, TUV, SGS or as your requirement to do test by the third party |

| Delivery | 10-15 days for sample, 30 -35days for bulk order |

| Packing | Steel Pallet, Plywood pallet, plywood box or as per your requirement |

| Inspection | IQC, IPQC,FQC,QA |

| Industry We Service | Automotive, Agriculture, Construction, Electrical, Electronic, Home Appliances, Medical, Marine, Machinery, Furniture, Food, Lighting,Telecommunication etc |

| Customers | USA,Canada, Mexico, Australia, New Zealand, Germany,UK, Spain, Switzerland, Franch etc |

Guangju (Kunshan) Precision Hardware Co., Ltd is a company specializing in the precision machining of metal components. Guangju is located in Kunshan, China, the company has been deeply engaged in the metal parts processing industry for more than ten years, providing customers with professional and comprehensive technical consulting, sample production, mass production and other complete solutions.

Guangju uses technology to drive the pace of progress, with high-quality products and services, aims to continue to create value for customers. Our team of seasoned experts offers a comprehensive range of solutions, including automotive metal component prototyping (body-in-white parts, soft stamping tooling, prototype samples for DV, EV, and PV), precision metal part production, electronic metal prototyping, industrial prototype development, small-batch production, mass stamping production, and the design and fabrication of metal stamping engineering tooling/progressive tooling.

Our products primarily serve the automotive, energy storage, medical, aerospace, and household electronic appliance sectors. Our commitment to quality is guaranteed by high precision of production equipment and stable & reliable process flow. Equipped with 3D/2D/ultra-precision laser cutting machines, CNC bending machines, CNC machining centers, hydraulic presses, punch presses, projection welding machines, arc welding robots, and riveting buckers. We have a complete set of trial production process capabilities, spanning product development, process design, feasibility analysis, soft tooling design, ultra-thin sheet precision cutting, wire cutting, laser cutting, metal drawing, five-axis 3D cutting, CNC bending, CNC turning and milling, 3D printing, assembly welding, and surface treatment. Adhering to stringent quality control standards, we offer high-quality products and technical support.

Our comprehensive range of testing equipment includes three dimensional measuring instrument, blue light scanners, articulated arms, projectors, universal electronic testing machines, and weld fusion depth testing machines. We provide dimension inspection reports, functional test reports, custom fixtures, and so on. We have got a number of invention and utility model patents, obtained ISO9001: 2015 and IATF16949: 2016 quality management system certification. To build the company image with high quality and create value for customers has always been the motto of Guangju. So far, it has maintained long-term stable cooperative relations with a number of internationally renowned companies. Looking forward to the future, Guangju (Kunshan) will continuously expand the horizons of product value chains and aspire to become a highly competitive, full-service provider of metal components.

Q1. What are your main products?

A: We specialize in manufacturing sheet metal products like laser cutting, bending, stamping, deep drawing, welding etc.

Q2. What surface treatment can you provide?

A: Powder coating, zinc plating,hot-dip galvanizing, polishing, wet paint, anodic oxidation, electrophoretic paint, passivation,etc.

Q3. Can I get some samples before mass production?

A: Yes, we can make samples per your drawings before mass production. We can use golden samples as quality standard for future mass production.

Q4. What is the minimum order size / value you accept?

A: We accept order quantity with around 100 pieces as a small quantity to test the market.

Q5. What's the delivery time?

A: In generally, it will take about 20- 25 days to finish one order.

Q6. What's your payment term?

A: Usually it is 50% down payment and 50% before shipment. Payment term is negotiable.

Q7. Do you provide OEM/ODM service?

A: Yes, we do both OEM and ODM.

Q8. How do you control the quality?

A. We are ISO 9001 certified . We use 5S quality control tool and have a dedicated QA team.

B. We will always make a sample to you to conform first, then a small batch run before mass production order. For a sample order, you can usually make a 50% down payment and only pay the remainder after satisfactory result.

C. Regarding to the key point dimension, we can also make the special fixture to inspect them.

D. From the material income to finial production inspection, we can keep the inspect report for 3-4 years to trace the quality."

Q9. What is Yixing technology's role if the parts are not of sufficient quality?

A: We will manage problem solving, root-cause-analysis, and be constantly on top to redo the parts. We can provide 8D report if customer needs.

Q10. Is Client's intellectual property well protected by Yixing technology in China?

A: Yes, we protect the clients' intellectual property well. Many clients sign NDA with us and we never face any difficulties. We are interested in long-term relationship with our clients and not in a one-shot deal.

Q11. What do you need for quotation?

A: We need pdf drawings or 3D drawing in the initial stage. If you can provide your current samples, it will also be great!

Q12. What's your quote time?

A: Normally, it is up to 3 days. The more detailed information you can provide, the more precise cost we can quote.

Q13. What's your after-sale service?

A: From our company side, we would like to provide our best service to you. If any products are with quality problems, we will replace at our expense. For your benefit, we would like to establish a clear quality inspection criterion at the beginning stage of the project. We also have an CRM system to keep work history with all customers to follow up your overall experience with us.

Q14. Can we visit your factory?

A: Yes, you are very welcome to visit and audit our factory.