- Overview

- Product Parameters

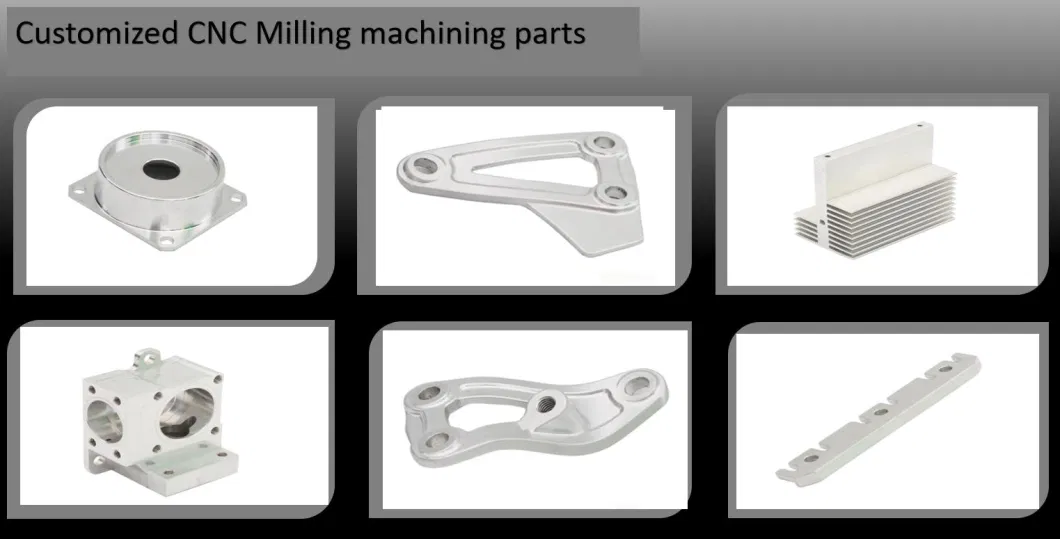

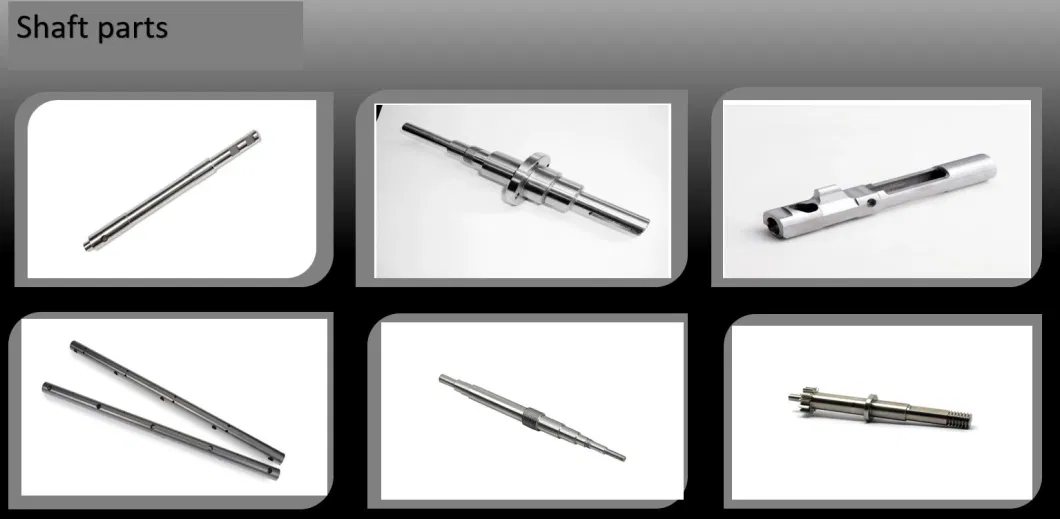

- Detailed Photos

- New Products dispaly

- Our Advantages

- Packaging & Shipping

- FAQ

Basic Info.

Model NO.

Custom

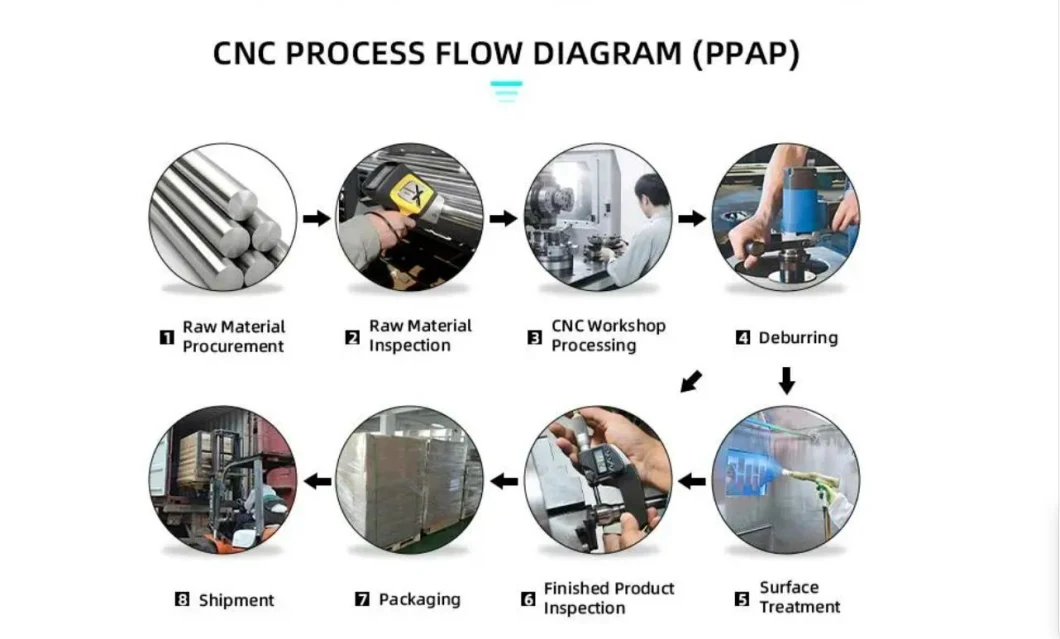

Production Type

Mass Production

Machining Method

CNC Milling

Material

Nylon, Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron

Processing Time

Leadtime of Mass Production:10-20days

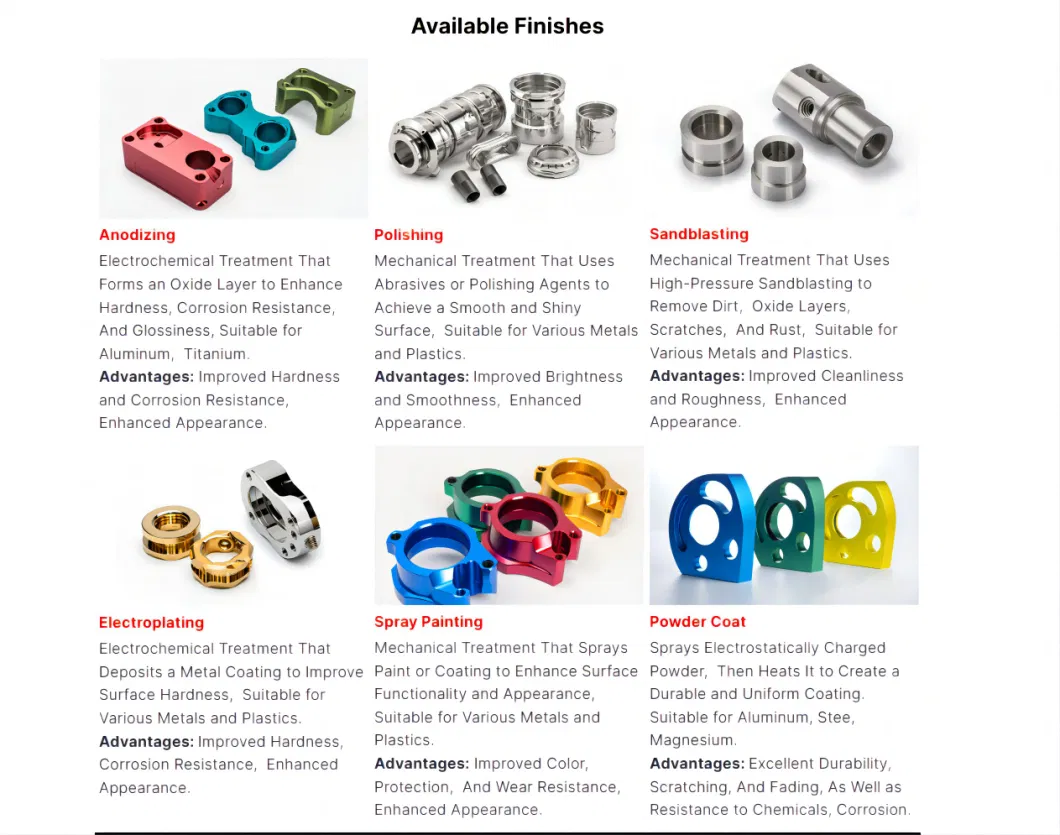

Surface Finish

Anodized/Plated/Customized

Tolerance

+-0.001

Price

Competitive Price

Transport Package

PE Bag, Carton, Pallet

Specification

0.1~1000mm

Trademark

AS

Origin

China

Production Capacity

500000/Year

Packaging & Delivery

Package Size

10.00cm * 10.00cm * 10.00cm

Package Gross Weight

0.010kg

Product Description

Industry-specific attributes

| CNC Machining or Not | Cnc Machining |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys |

Other attributes

| Place of Origin Guangdong, China Type Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping Micro Machining or Not Micro Machining Model Number Non-standard Brand Name AS Description Cnc Aluminum Spare Parts Tolerance +/- 0.001mm Certification ISO 9001; 13485; 14001 Material Aluminum, Stainless steel, Brass, Plastic, etc. Surface treatment Plain, Anodizing, Power coating, Plating, Passivation, etc. Process CNC precision machining QC Control 100% QC on critical dimensions, QC report available Cost Control Skilled workers with most efficient production process design Application Electronics, Industrial equipment, Medical field, Auto industry, etc. Service Customized OEM |

| Supply Ability 50000 Piece/Pieces per Month |

Custom Aluminium Rapid Prototyping CNC Machining Parts Manufacturer

Customized products according to your drawings

| MATERIAL AVAILABLE | |||||

| Aluminum | Stainless Steel | Brass | Copper | Plastic | Iron |

| AL2024 | SS201 | C24000 | C10100 | POM | Q235 |

| AL5052 | SS301 | C26000 | C11000 | PEEK | Q345B |

| AL6061 | SS303 | C28000 | C12000 | Nylon | 1214 / 1215 |

| AL6063 | SS304 | C35600 | C12200 | Delrin | 45# |

| AL6082 | SS316 | C36000 | etc. | etc. | 20# |

| AL7075 | SS416 | C37000 | | | 4140 / 4130 |

| etc. | etc. | etc. | | | etc. |

| SURFACE TREATMENT | |||

| Aluminum Parts | Stainless Steel Parts | Steel Parts | Brass Parts |

| Clear Anodized | Polishing | Zinc Plating | Nickel Plating |

| Color Anodized | Passivating | Oxide black | chrome plating |

| Sandblast Anodized | Sandblasting | Nickel Plating | Electrophoresis black |

| Chroming | Laser engraving | Powder Coated | Powder coated |

| Brushing | Electrophoresis black | Heat treatment | Gold plating |

| Polishing | Oxide black | Chrome Plating | etc. |

| etc | etc | etc | |

| Quotation | According to your drawing(size, material, required technology, etc) | |||

| Tolerance | +/-0.001 mm - 0.01 mm (Customized avaiable) | |||

| Surface Roughness | Ra0.2 - Ra3.2(Customized avaiable) | |||

| Processing | Turning, Milling , Drilling, Auto lathe, Tapping, Surface treatment, etc. | |||

| Drawing Formats | PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF | |||

| We can make any products you want ! | ||||

| SURFACE TREATMENT | |||

| Aluminum Parts | Stainless Steel Parts | Steel Parts | Brass Parts |

| Clear Anodized | Polishing | Zinc Plating | Nickel Plating |

| Color Anodized | Passivating | Oxide black | chrome plating |

| Sandblast Anodized | Sandblasting | Nickel Plating | Electrophoresis black |

| Chroming | Laser engraving | Powder Coated | Powder coated |

| Brushing | Electrophoresis black | Heat treatment | Gold plating |

| Polishing | Oxide black | Chrome Plating | etc. |

| etc | etc | etc | |

| Quotation | According to your drawing(size, material, required technology, etc) | |||

| Tolerance | +/-0.001 mm - 0.01 mm (Customized avaiable) | |||

| Surface Roughness | Ra0.2 - Ra3.2(Customized avaiable) | |||

| Processing | Turning, Milling , Drilling, Auto lathe, Tapping, Surface treatment, etc. | |||

| Drawing Formats | PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF | |||

| We can make any products you want ! | ||||

Why Choose Us

Product quality is guaranteed, with precision testing equipment such as CMM, RoHS tester, Roughness tester, 2.5D, etc. Which can meet the testing needs of various precision component products.

Good Preformance

Q1: How Can I Get a Quote?

A1: If You Are a Professional, You Can Get a Quote by Sending Drawings and Requirements or Instructions. We Will Reply to You as Soon as Possible and Provide You with a Quote.

If You Are Not a Professional, You Can Tell Us Your Specific Needs. Our Professional Team Will Provide You with Multiple Customized Solutions Based on Your Needs and Provide You with a Quote.

Q2: Are My Drawings Safe?