- Overview

- Product Description

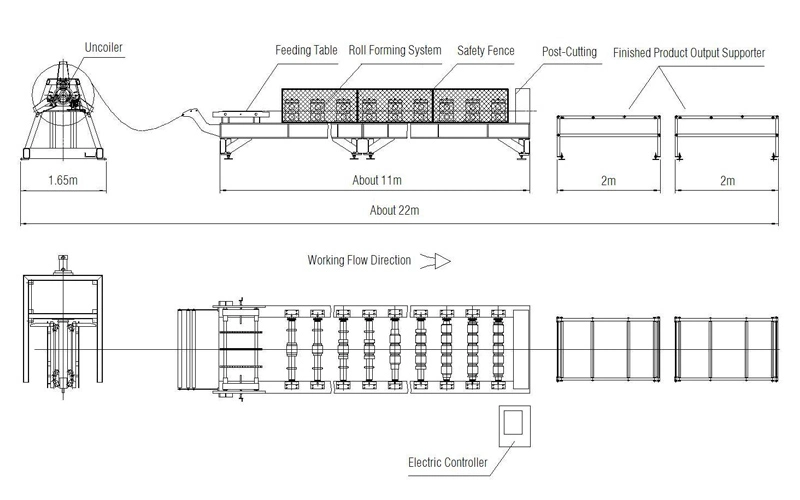

- Working flow

- Product Parameters

- Detailed Photos

- Packaging & Shipping

- Certifications

- Company Profile

Basic Info.

Usage

Roof, Wall

Transmission Method

Machinery

Raw Material

PPGI

Material Thickness

0.3-0.6mm

Machine Color

Customized as Customer′s Need

Roller Material

45# Steel

Shaft Material

45# Steel

Main Market

Africa ,Southeast Asia ,South America etc

Forming Speed

6-15m/Min

Motor

4kw

Hydraulic Oil Pump

3kw

PLC

Delta From Taiwan

Invertor

Delta From Taiwan

Screen

Touch Screen ,Delta

Language

Chinese,& English ,or Customized as Your Need

Origin

Hebei, China, Mainland

HS Code

8455221000

Production Capacity

200 Sets /Year

Product Description

The whole line includes 6 parts altogether ,

The whole line includes 6 parts altogether ,

Decoiler --Feeding table --Roll forming machine body--Computer control system --Cutting blade --Finished panel --Run out table

| NO. | Item | Specification |

| Material | Raw material | Galvanized steel coil |

| Material thickness | 0.3-0.6mm | |

| Machine body | Roller stations | 13 |

| Shaft material | High grade 45# steel | |

| Shaft diameter | 75mm solid | |

| Roller material | High grade 45# steel | |

| Middle plate thickness | 20mm | |

| Machine size | 6*1.2*1.5m | |

| Productivity | 8-15m/min | |

| Cutter | Material | CR12 |

| Method | Hydraulic cutting | |

| Power | Driving way | Chain 1 inch |

| Motor | 7.5KW servo motor | |

| Hydraulic oil pump | 4KW | |

| Voltage | 380V,50HZ ,3 PHASE or customize as your need | |

| Control system | PLC | Delta from Taiwan |

| Invertor | Delta from Taiwan | |

| Screen | Touch screen ,Delta | |

| Encoder | Omron from Japan | |

| Language | Chinese & English or as your request | |

| Decoiler | 5T manual | Free |

| Receiving table | 3m manual | Free |

Corrugatted Roofing Sheet Machine /Corrugated Roof Sheet Roll Forming Machine /Corrugated Sheet Making machinery /Wave Profile Steel Roll Forming Machine

| This is corrugated roof panel sheet roll forming machine ,this roll forming machine is widely used in norways ,material thickness is 0.18-0.5mm ,some customers prefer choosing this type of roll forming machine because of its good quality as well as reasonable price ,we can also make as your request if you can offer sample or design drawing |

| Roll forming machine body Roof roll forming machine with high speed and low price ,roller & shaft material is 45# steel Roller surfaces polish, hard plating dealing Polished surface and heat treatment towards molds can keep the molding plate surface smooth and not easy to be marked when it is being stamped |  |

| Hydraulic cutting device Controlled by oil pump Automatic cutting as target products length Blade material: Cr12, quenching treatment |

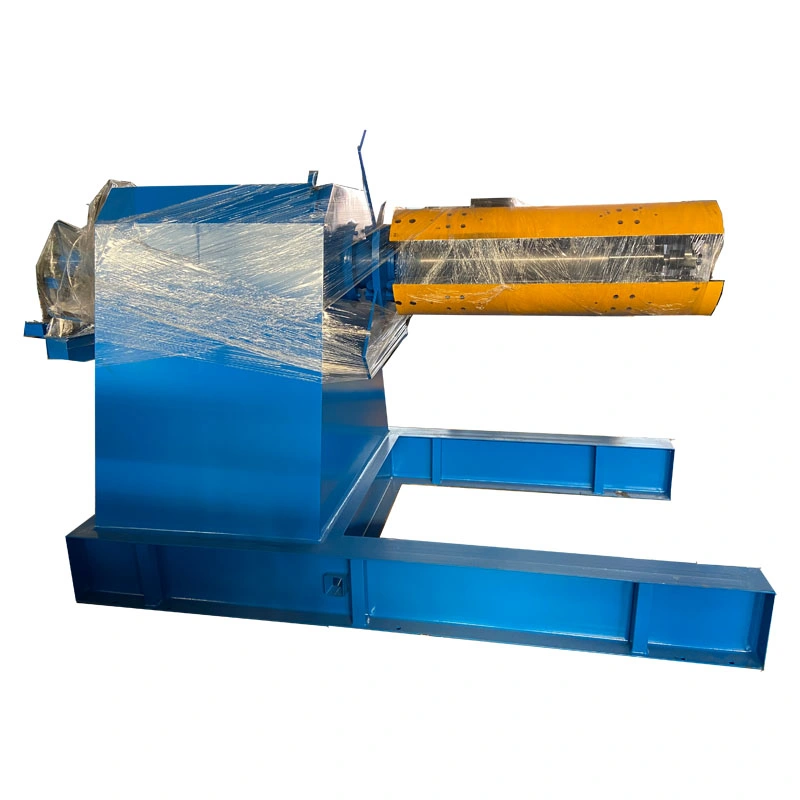

| Decoiler Pic just for reference,It is used to stand the steel coil and uncoil, keep them working stably. Loading capacity: 10tons |  |

Main market

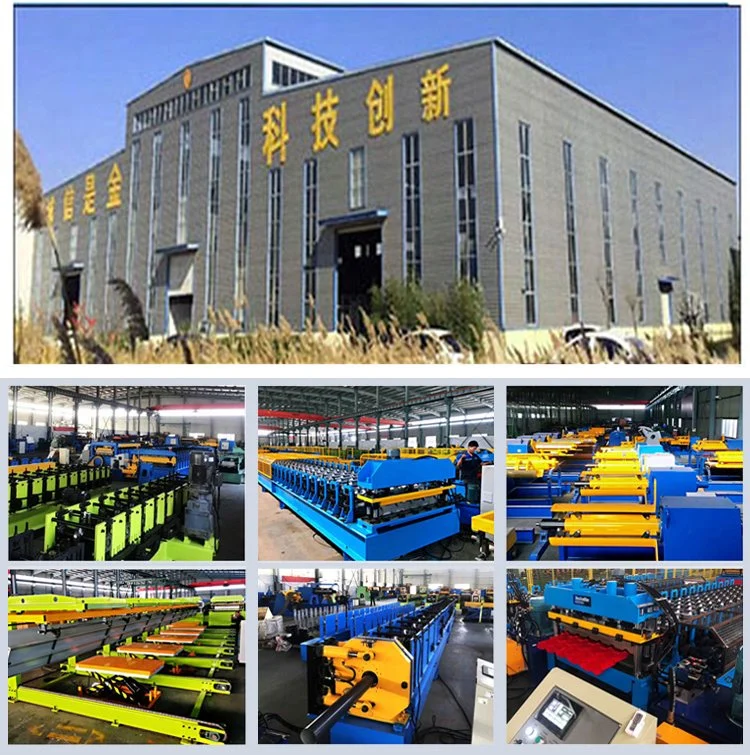

SANYANGTONGTAI MACHINERY CO.,LTD

Botou Sanyangtongtai Machinery Co.,ltd is a leading manufacturer for steel plate coiling

machinery,cold-bending & rolling steel plate shaping machineries and automatic production lines.The products are mainly used in steel structure industry for producing C&Z type purlin,colored wall and floor protecting steel plate, thermal insulating plate and

load-bearing plate of buildings, and other complementary thin wall cold-bending shaped steelplates,expresswayrailings,colorfuldecorating and protecting steel plates for high-grade steel stucture residendces.

machinery,cold-bending & rolling steel plate shaping machineries and automatic production lines.The products are mainly used in steel structure industry for producing C&Z type purlin,colored wall and floor protecting steel plate, thermal insulating plate and

load-bearing plate of buildings, and other complementary thin wall cold-bending shaped steelplates,expresswayrailings,colorfuldecorating and protecting steel plates for high-grade steel stucture residendces.

FAQ

Q1. What's your payment terms and delivery time?A1: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after

your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will

arrange production. About 30-45 days for delivery.

Q2. Do you have after-sales support?

A2: Yes, we are happy to provide advice and we also have skilled technicians available across the world.

Q3. Do you sell only standard machines?

A3: No, most of our machines are built according to customers specifications, using top brand components.

Q4. What will you do if the machine is broken?

A4: We provide 18 months free warranty and free technical support for the whole life of any machine. If the broken parts can't

repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond

the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the

equipment.

Q5. Can you be responsible for transport?

A5: Yes, please tell me the destination port or address. we have rich experience in transporting.

Q6. How to visit your company?

A6: 1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour). 2) Fly to Shanghai Airport: By high

speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.