Basic Info.

Model NO.

Customized

Production Capacity

Long-Term Supply

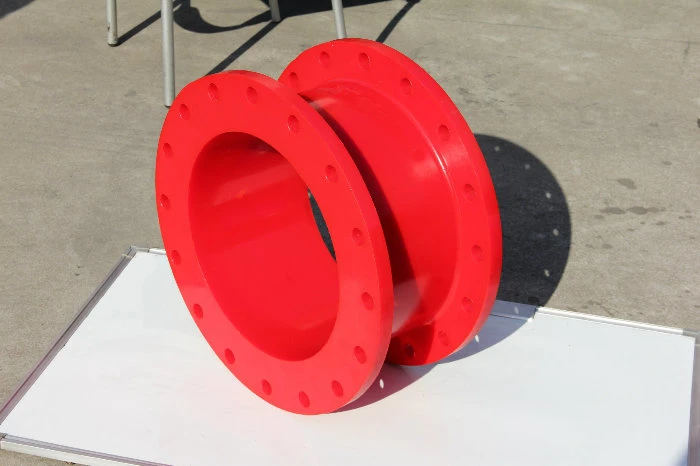

Product Description

Urethane elastomer are excellent in anti-abrasion and chemical resistance, tensile strength, high flexibility, high pressure load, wear resistance, high strength, shock absorption and strong, tear resistant, resistant to radiation, high load and shock absorption cushioning. It is good adhesion to metal and with wide range of hardness from Shore 10A - 64D. For superior shock absorption, shock absorption cushioning pad, impact-resistant than metal springs, not to hurt the mold.

Applications:

Widely used in mechanical vibration plate, punching, stamping and other industry equipment.

Our PU parts are suitable for all type PUMP, Due to excellent anti-abrasion, the using period are largely prolonged than the steel parts.

As long as you give us the drawing, we can produce it for you.

Photos:

Applications:

Widely used in mechanical vibration plate, punching, stamping and other industry equipment.

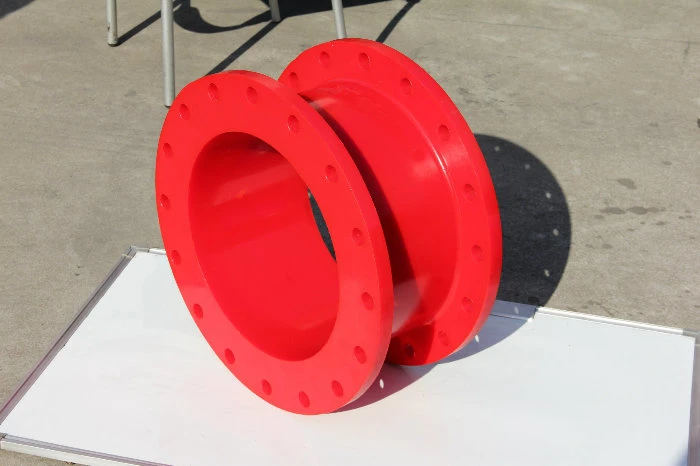

Our PU parts are suitable for all type PUMP, Due to excellent anti-abrasion, the using period are largely prolonged than the steel parts.

As long as you give us the drawing, we can produce it for you.

| 1 | It is the most versatile, toughest, abrasion resistance elastomer available. It is as soft as Shore A durometer 10 and hard as Shore D scale durometer 85. |

| 2 | It could be cast into practically any shape, size or complex geometry desired wheels, gears, O rings, gaskets, tires, roller blades, skate boards etc. |

| 3 | It can be formulated with high resistance to stresses and it tends to maintain shape and mechanical properties aster fatigue stressing. |

| 4 | Casting Polyurethane maybe pigmented to resist degradation by elevated atmospheric oxygen and ozone atmospheric concentrations. |

| 5 | Many cast polyurethane elastomers compounds remain flexible at extreme low temperatures and possess outstanding resistance to thermal shock. Low temperature resistance of polyurethanes make cast parts very practical in extreme arctic conditions. |

| 6 | Casting polyurethane parts can be made flame resistance by incorporating flame retardants into their formulas. |

| 7 | Polyurethane can be cast with coefficients of friction varying from very low, for items like bushings, bearings or wear strips, or very high, for items like tries or rollers. |

Photos: