Basic Info.

Productivity

180m²/h

Feeding Height

1390mm

Vibrating Amplitude

2.2mm

Certification

ISO9001: 2000, CE

Condition

New

Color

Accordingly

Material

Carbon Steel (Mixing Tank-8mm, Temporary Hopper-6m

Capacity

10-100m3/H

Total Power

68kw

Max.Pumping Height

20

Max. Pumping Distance

200

Transport

by Container

Accessory 1

Mixing System

Accessory 2

Storage System

Accessory 3

Water Tank

Accessory 4

Additive System

Accessory 5

Air Conditioner

Transport Package

Laminated Packaging

Specification

accordingly

Trademark

SDCAD

Origin

China

HS Code

8474390000

Production Capacity

5000 Sets/Month

Product Description

Grout Mixing Plant

Grout mixing station is a grout mixing and pumping system designed to fit inside a shipping container making it highly portable and easy to transport between job sites. This type of equipment is commonly used in construction and civil engineering projects to mix and inject cement grout and other materials to strengthen soil or concrete structures. Grout mixing stations, Our container type grout mixing stations feature containerized design, making them easy to transport, install and use, and can meet various on-site requirements, as well as be used in conjunction with other equipment. can adapt to a variety of complex const.  FEATURES AT A GLANCE

FEATURES AT A GLANCE

Application: Anchor injection, Jet grouting, Drilling, Concreting, Cavity filling, Bottom injection Tunnel applications, Dam applications

FEATURES AT A GLANCE

FEATURES AT A GLANCE Size: GP5 ~100 m3/h

Type: Container-type grout mixing station, Jet Grout Plants, Application: Anchor injection, Jet grouting, Drilling, Concreting, Cavity filling, Bottom injection Tunnel applications, Dam applications

Customized Solution is the Core concepts of SDCAD

Why choose us?

Our cement silo is designed to match with flow requirement of cement plant, and we have 20+ years of experience in cement equipment manufacture and EPC project. The cement silos produced by SDCADI is easy to install, safe and reliable, and win a good reputation on the market.

We own a professional R & D, design, production, installation team, and provide users with one-stop service, including the process design, automatic control and steel plate warehouse, transportation, cleaning, dust removal equipment manufacturing, installation, commissioning and personnel training.

We can provide different types of cement silos to meet the requirements of clients, three types of Mixing Plants (Jet Grout Plants, mud units, batch units, batch mixers )

Gruot plant with bolt silo Grout plant with big bag silo Grout plant with container silo

Gruot plant with bolt silo Grout plant with big bag silo Grout plant with container silo

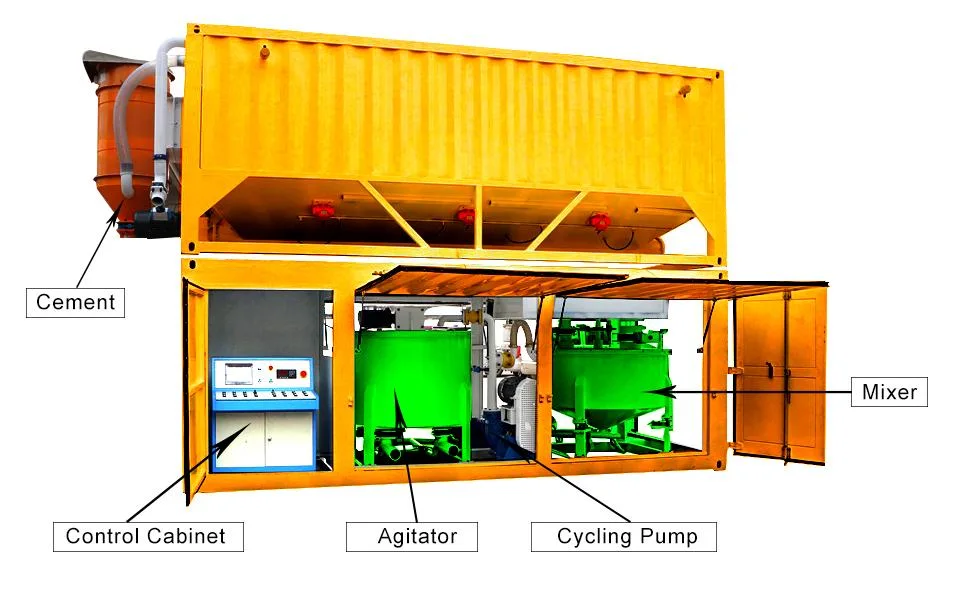

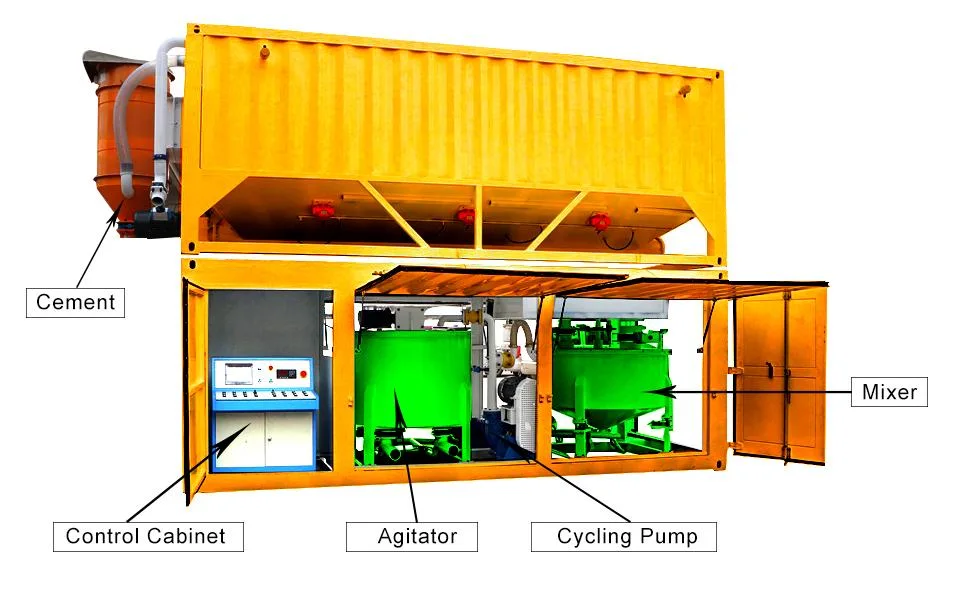

Agitator Control Cabinet Mixer

Agitator Control Cabinet Mixer

Full Process Solution Provider - SDCAD

1.Automatic grouting equipment is with CE, ISO certification.

2.Compact structure, a whole plant with mixing and grouting.

3.Automated mixing and grouting plant is simple operation and easy maintenance.

4. There are two operation modes: automatic mode and manual mode.

5. Less spare parts ensure low maintenance costs.

6. High speed vortex mixer ensures mix quickly and evenly.

7.The proportion of materials in the formula can be adjusted freely.

8. It can realize automatic configuration and replenishment of materials.

9. Flameproof electric cabinet,protection grade IP56.

10.Tank body manufactured by the thicker plate for more reliable work and longer use life.

2.Compact structure, a whole plant with mixing and grouting.

3.Automated mixing and grouting plant is simple operation and easy maintenance.

4. There are two operation modes: automatic mode and manual mode.

5. Less spare parts ensure low maintenance costs.

6. High speed vortex mixer ensures mix quickly and evenly.

7.The proportion of materials in the formula can be adjusted freely.

8. It can realize automatic configuration and replenishment of materials.

9. Flameproof electric cabinet,protection grade IP56.

10.Tank body manufactured by the thicker plate for more reliable work and longer use life.

11. Standard seal parts to ensure excellent seal quality.

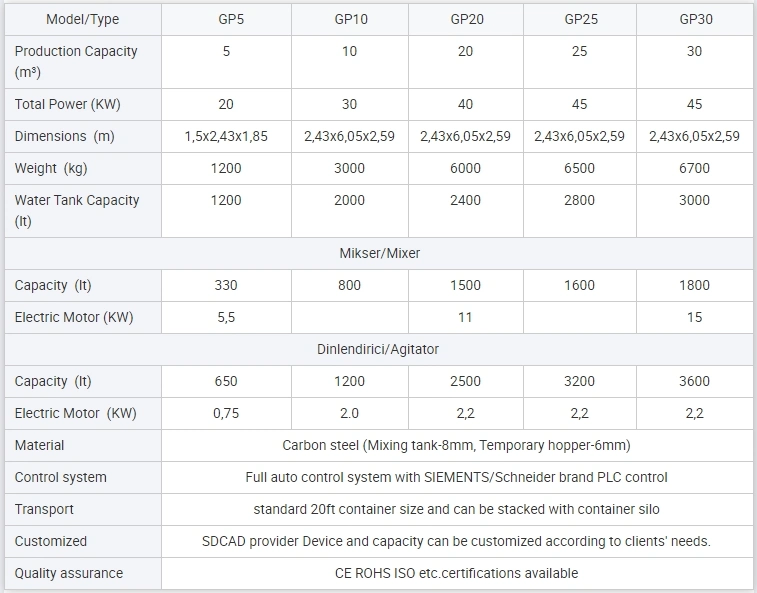

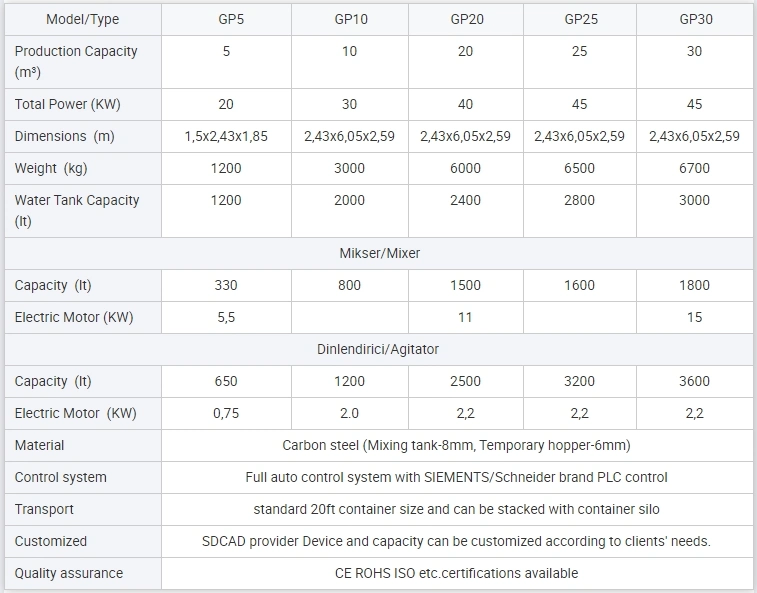

PRODUCT SPECIFICATIONS

PRODUCT CONFIGURATION

PRODUCT CONFIGURATION

Advantages of SDCADI's Grout Mixing Plant * High-speed Colloidal Grout Mixer

Advantages of SDCADI's Grout Mixing Plant * High-speed Colloidal Grout Mixer

* Main pipeline valves are all pneumatic valves

* Mixture, cycling pump and agitator have automatic cleaning function

* Cement can be added by cement silo or screw feeder automatically

* The preparing of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid components

* Two modes of operation:fully automatic mode and manual mode

* Easy to operate and maintain

* Up to 8mm particle size

* Equipped with some ceiling lamps, for illuminating the different working areas.

* Can be placed directly in the 20ft cabinet

Product case

Product case

Bolted silo Container Horizontal Silo Big Bag Hopper

Bolted silo Container Horizontal Silo Big Bag Hopper

PRODUCT CONFIGURATION

PRODUCT CONFIGURATION

Advantages of SDCADI's Grout Mixing Plant

Advantages of SDCADI's Grout Mixing Plant * Main pipeline valves are all pneumatic valves

* Mixture, cycling pump and agitator have automatic cleaning function

* Cement can be added by cement silo or screw feeder automatically

* The preparing of ternary or quaternary compound mixing is possible, with either one or two liquid components and one solid components

* Two modes of operation:fully automatic mode and manual mode

* Easy to operate and maintain

* Up to 8mm particle size

* Equipped with some ceiling lamps, for illuminating the different working areas.

* Can be placed directly in the 20ft cabinet

Product Show

• Grout Plants range includes different sizes equipment with production.

• The continuous mass transfer between the two zones ensures maximum possible homogeneity of the mixture.

• Absolutely minimal sedimentation of the mixture.

• High mixing capacity due to short mixing time.

• Lowest possible use of raw materials.

• Operator cabin with full automatic control panel board.

• The continuous mass transfer between the two zones ensures maximum possible homogeneity of the mixture.

• Absolutely minimal sedimentation of the mixture.

• High mixing capacity due to short mixing time.

• Lowest possible use of raw materials.

• Operator cabin with full automatic control panel board.

Product case

Product case

| Pre-Sales Service | After-Sales Service |

| Customer consultant 24 hour online; Engineer team provide design drawing; Skilled staff responsible for production; Take pictures for all Production process. | Provide installation instruction; Solve any problems involved; Tell the machinery maintain guidance; Regular monthly sales tracking. |

Related Products

FAQ

May you introduce your Factory?

Our factory is with 10,000m2 factory floor area. More than 100 workers will service for you. Our factory is located in Shandong -the only province which cover all industrial sectors in China.

What's the Advantage of your products?

Full Process Solution Provider of Mixing, Storage, Conveying.

May you introduce your Factory?

Our factory is with 10,000m2 factory floor area. More than 100 workers will service for you. Our factory is located in Shandong -the only province which cover all industrial sectors in China.

What's the Advantage of your products?

Full Process Solution Provider of Mixing, Storage, Conveying.

Our engineers team provide Customized Solution for every project!

What is your Delivery time?

3-7 days for spare parts; 10-20 days for simple machine. 30-50 days for production line.

What is your Delivery time?

3-7 days for spare parts; 10-20 days for simple machine. 30-50 days for production line.

What Certificate do you have to ensure quality?

CE certification is provided.

CE certification is provided.

ISO health, ISO Quality, ISO Environment are provided.

Do you have Quality Check QC Service?

QC checking work is including from material, steel processing, welding, painting, electric system, test, delivery, installation. Quality check for full process

How can I Get Solution to my inquiry?

QC checking work is including from material, steel processing, welding, painting, electric system, test, delivery, installation. Quality check for full process

How can I Get Solution to my inquiry?

Pls send inquiry to us now,

More project and contact information more better. Engineers will make plan for you. Our Sales manager will Quote to you in the first time.

More project and contact information more better. Engineers will make plan for you. Our Sales manager will Quote to you in the first time.