- Overview

- Material List

- Fabricate after 3D Printing

- Why Us

- Our Team

Basic Info.

Model NO.

IP189

Delivery Time

Sample Day: Within 7 Days; Mass Production : 15~45

Tolerance

0.01+/- 0.005mm (Custom Available)

Transport Package

According to Customer Requirements

Trademark

Ideal Pro

Origin

Zhejiang

Production Capacity

10000/Week

Product Description

Huzhou Dear Industry Co.,Ltd.

Huzhou Dear Industry Co., Ltd. was established in 2008 with an injection molding factory and a die-casting factory, possessing professional injection molding production and zinc/aluminum alloy die-casting production capabilities, as well as corresponding mold design and manufacturing capabilities. The following is a list of our company's major production models. Our excellent business team can fully and efficiently communicate with customers, understand their ideas and intentions, and convey them to our technical department. Our outstanding team of engineers will provide customers with the best solutions based on their professional knowledge and from the perspective of cost, product quality, production stability, and other aspects according to the customers' needs.

Meanwhile, we also possess excellent resource integration capabilities to provide customers with one-stop-service. In our assembly workshop, four assembly lines can assemble parts into finished products and package them for shipping, saving customers the trouble of contacting multiple suppliers.

If you have any procurement or design needs for individual parts or complete products, please feel free to contact us. We are available 24/7 and look forward to communicating with you.

One-Stop-Service

We not only provide rapid prototyping services, including 3D printing and CNC machining, but also help our customers optimize their designs to meet the needs of mass production. We have capabilities in injection molding, die casting, sheet metal fabrication, CNC machining, and assembly, which enable us to turn designs into actual products on the shelf.

Case Study

Wecount HomeGym Kit

This case is very typical from us, very successful in both design and production. From the customer's initial idea, to the design that meets his idea, and confirmation and communication of T0 and T1 samples, every step brings us closer to success, finally reaches to the stable quality and competitive products.

It was not an easy process, but it certainly served our customers well and made them successful in business.

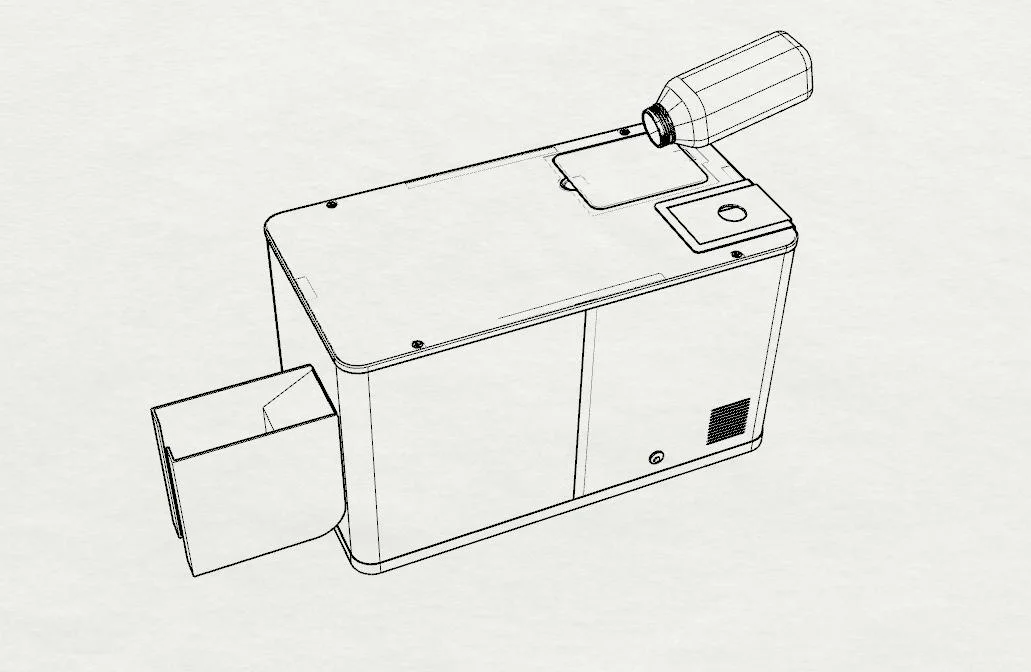

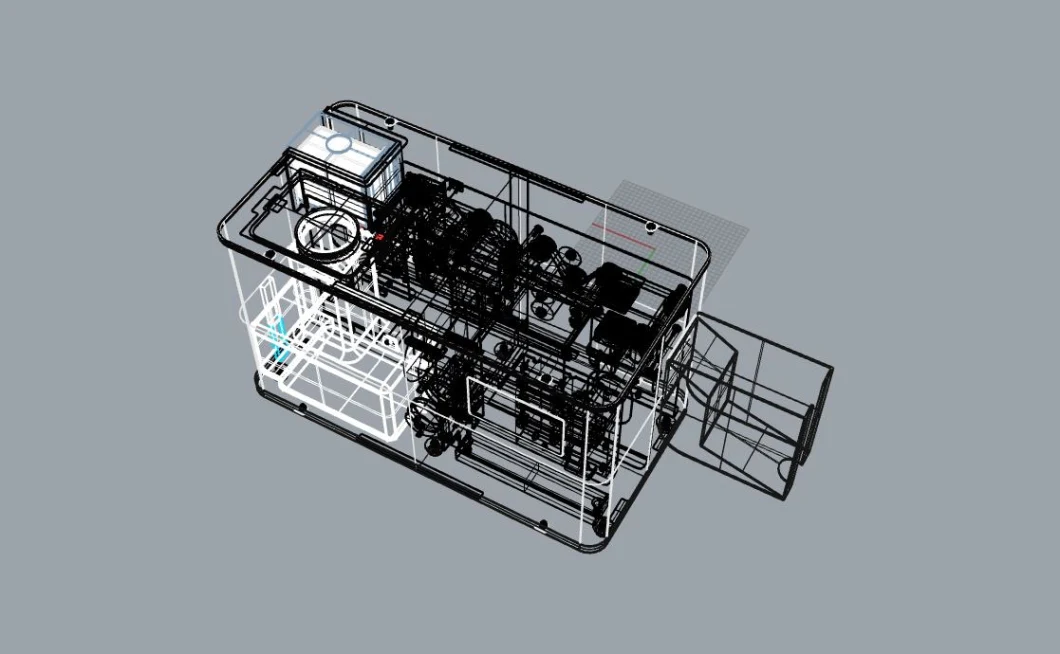

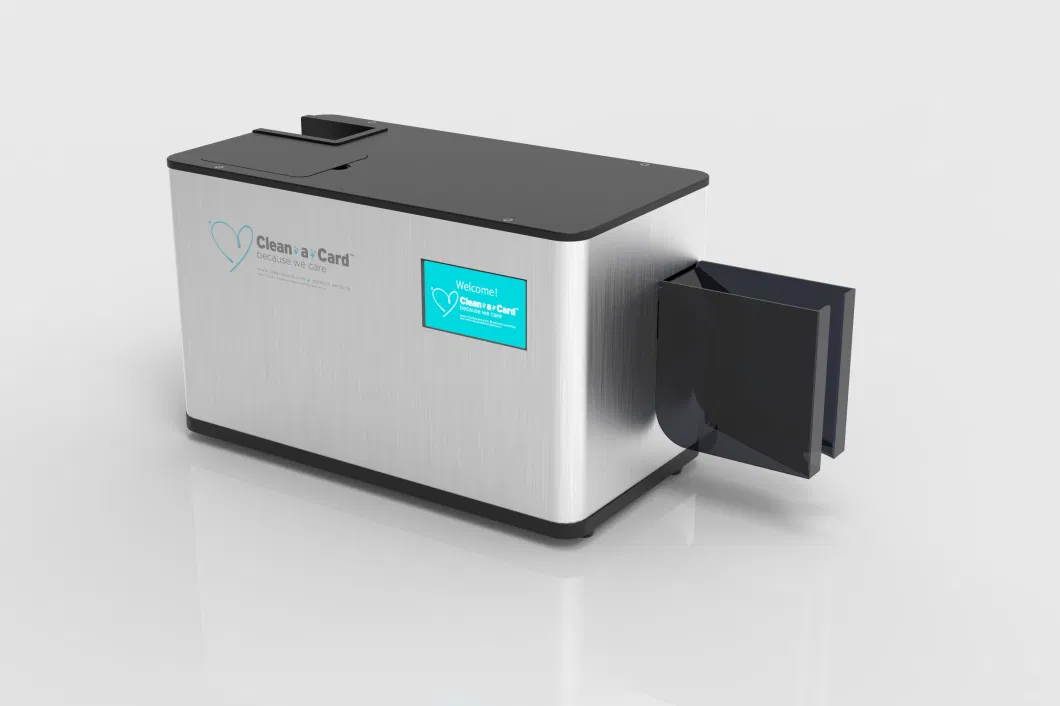

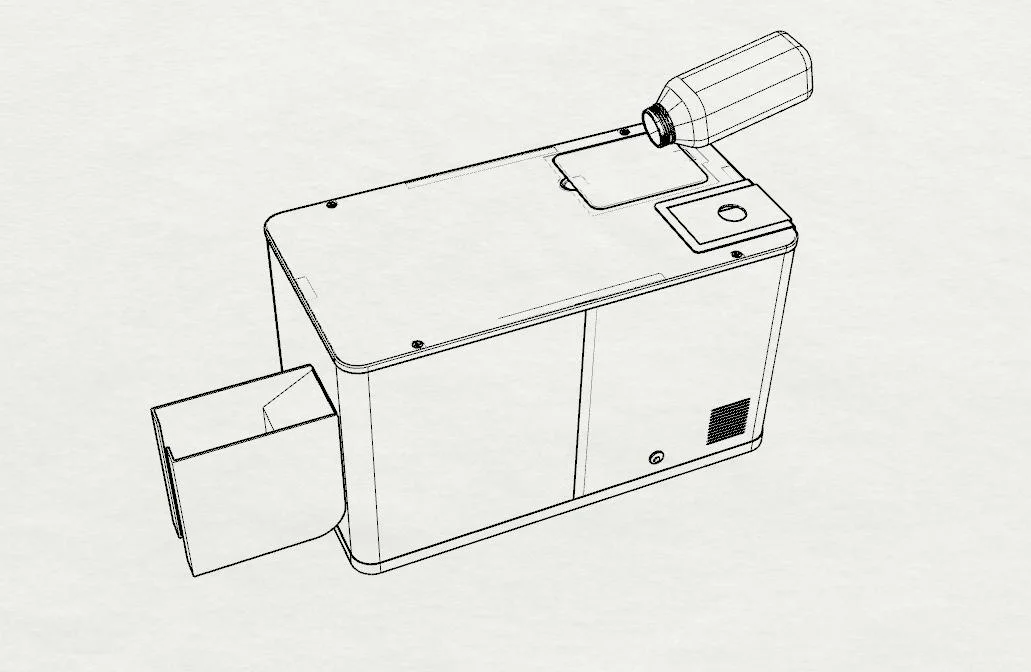

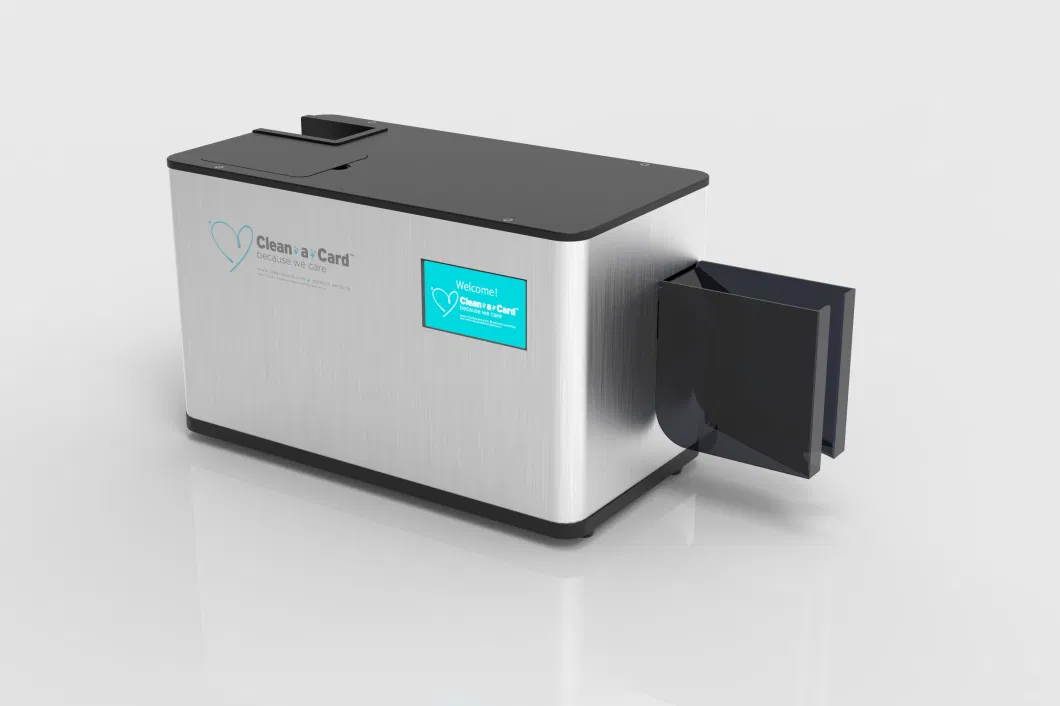

Clean A Card Machine

It was not an easy process, but it certainly served our customers well and made them successful in business.

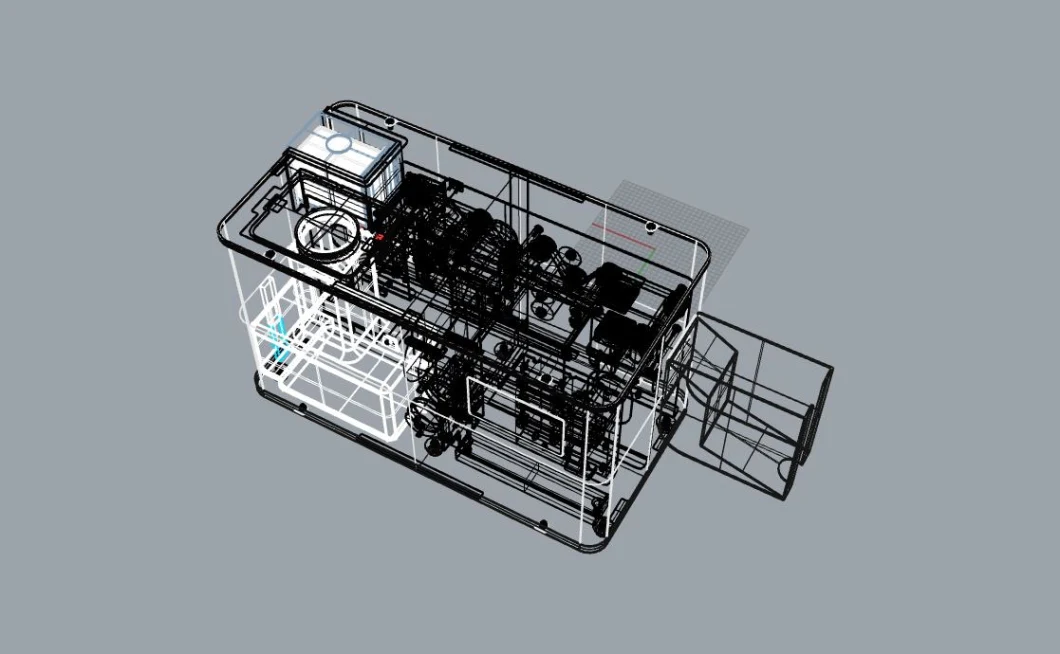

Clean A Card Machine

We have received a sample machine from the customer, but it is obviously can't be produced and not stable enough, and part of the design makes the cost of mass production very high. We have redesigned the machine to meet the demands of production and greatly reduce the cost.

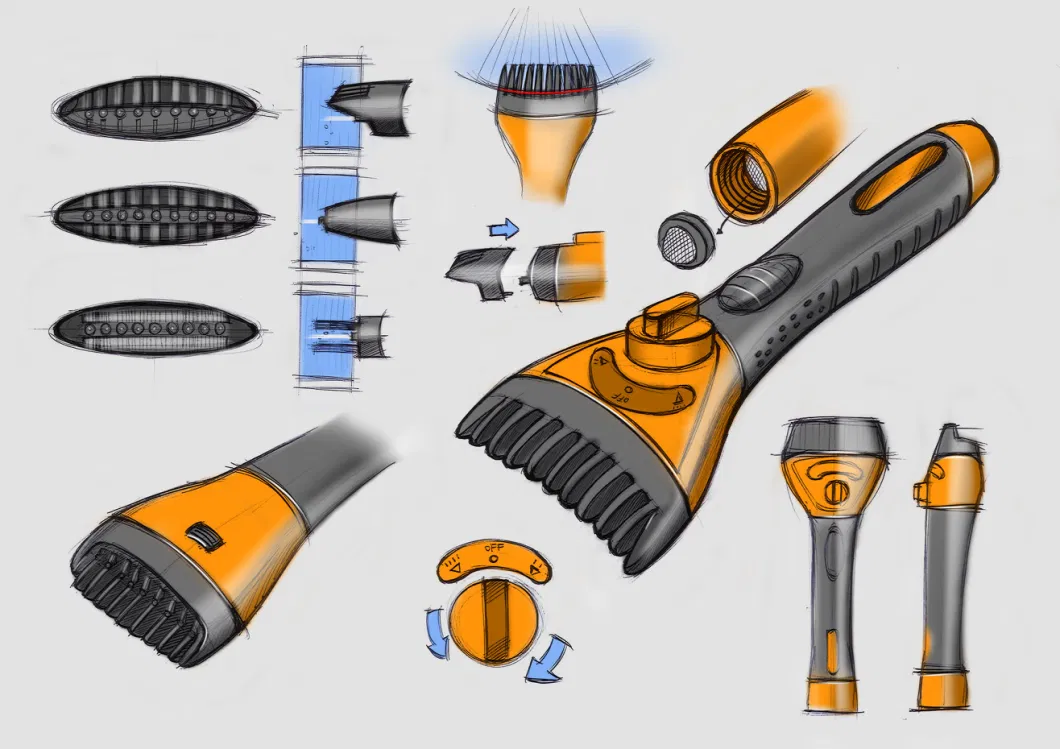

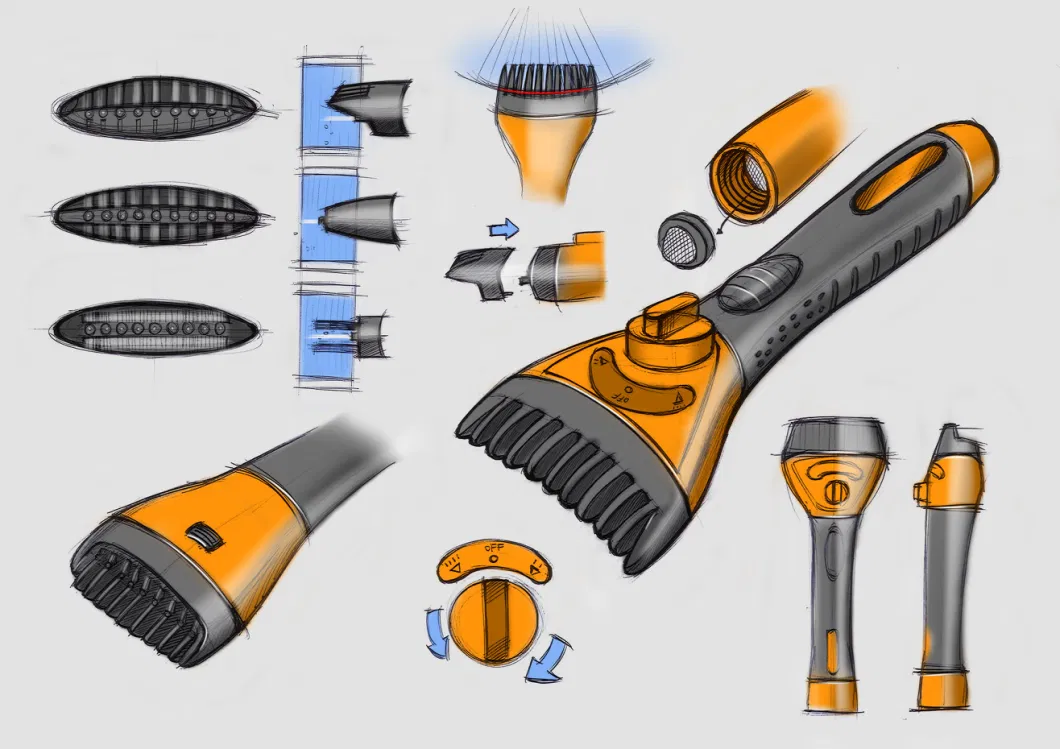

Car wash Tool

Car wash Tool

Our client need us to design the next generation of product to solve the issues of previous products. After listening to the customer's opinion, we made a new design, it reaches client's demand and have success on market.